Your Cart is Empty

We are pleased to announce the first Helweg Design product release of the new decade: our versatile Offset Pedal Mounting Bracket.

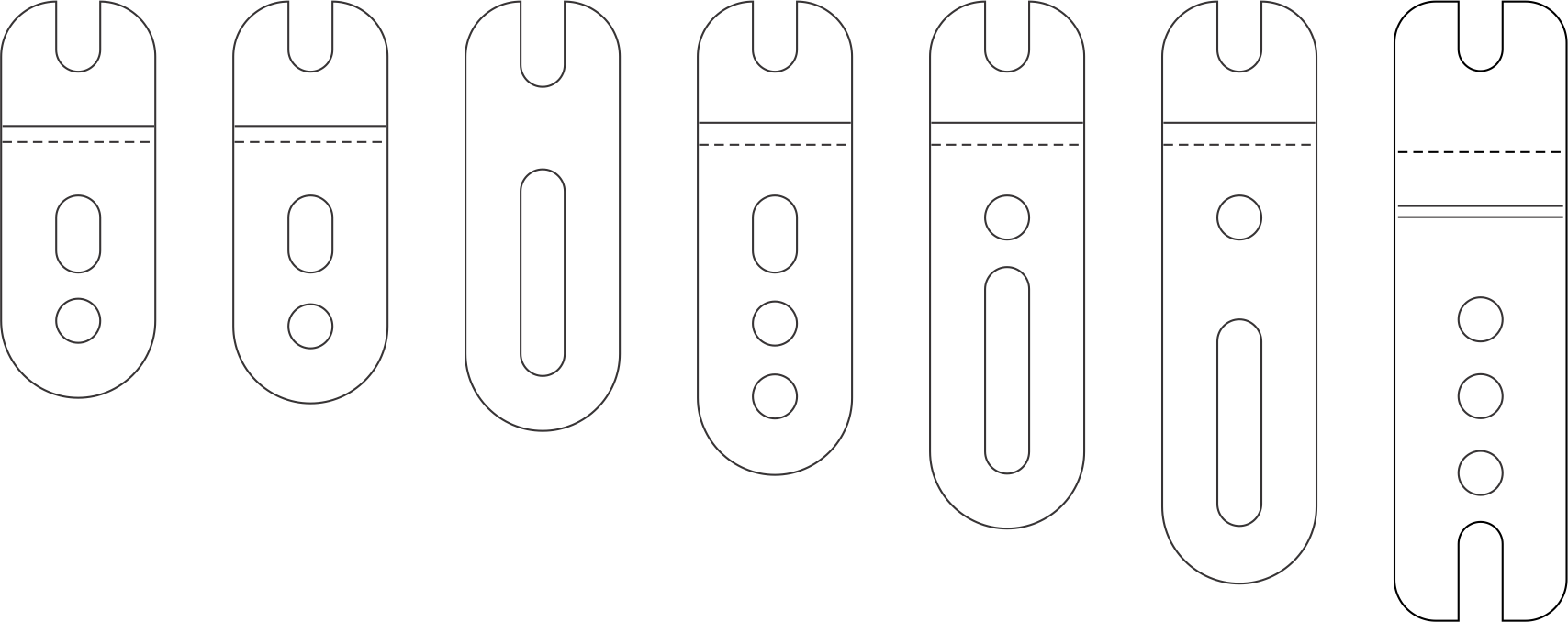

The new bracket is a refinement of our slotted Type-S bracket, designed for wah, volume, and expression pedals. A long mounting slot allowed the Type-S bracket to adjust to the varying enclosure-screw locations of many tricky-to-mount pedals. This versatility made them an essential part of our mounting system.

About a year ago, I began to work on an improved version 2 design, with several goals in mind.

2016 Type-S Bracket

My first goal was to eliminate the need for a spacer below the bracket by offsetting the bracket itself. This noticeably streamlines the look and makes pedalboard setup faster and easier. Equally beneficial, the bracket makes direct contact with the pedalboard for increased stability. The new bracket retains our open-end mounting slot, helpful for quicker release during setup and maintenance.

2020 Offset Bracket

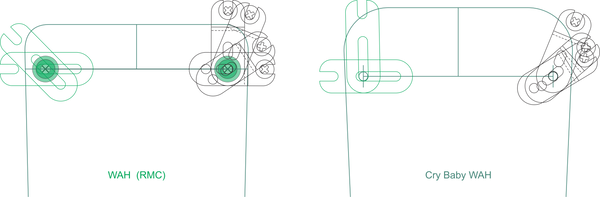

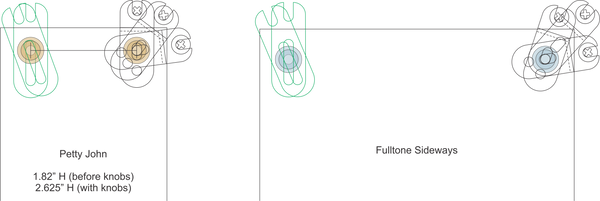

Over the years, I've documented the enclosure sizes and screw locations of many pedals requiring the Type-S brackets. Before sending a new design to our metal fabricator for prototyping, I spent a good amount of time comparing several concept drawings against the dimensions of my documented pedal specs. I pressed forward with the ideas that worked best.

I wanted to retain the versatility afforded by the long slot, but gain a closer-to-custom fit for pedals like Strymon and industry-standard expression pedals. I carefully fine-tuned the new bracket length and slot dimensions against the pedal specs until I had the customized-yet-adjustable fit I was looking for. This resulted in a precisely placed hole-and-slot combo. The small amount of metal added between the hole and the slot is significant, giving the pedal screw and washer 20-40% more surface area to grip on to.

Here is a sampling of my mock-up work.

The Offset Bracket launches with more hardware packs, including the choice of two, three, and four brackets per pack. For a pedal the size of a Strymon Deco, I like to use three brackets, but for a wah, which is heavier and receives much more foot force, I always use four brackets. The ability to order exactly what each unit needs keeps your pedal mounting project as cost effective as possible.

Hardware pack 2 includes everything needed to mount a wah, volume, or expression pedal.

Each hardware pack includes four 3M stick-on feet which are the exact height of the brackets. This keeps the weight and force of operation on the rubber feet—not on the brackets—and keeps the pedal level whether or not you place a bracket on every corner.

Wide-base counter-sunk washers for the pedal screws are also included. These effectively increase the head size of the screws holding the bracket against the pedal and give a slight amount of squeeze so you don't need to over-tighten the screw. This helps to achieve a solid grip while protecting the screw threads inside the pedal.

The new Offset Bracket accomplishes all my design goals. I'm very pleased with the results and have had a great time using them in my most recent board setups. We hope you will check them out and let us know what you think!

Visit the product page HERE.

Comments will be approved before showing up.